Translucent wood offers a fresh take on building materials, letting light shine through like glass while adding strength and improved warmth retention. This engineered product from natural timber could transform eco-friendly windows and more.

Discovery and Early Experiments

Researchers first stumbled on translucent wood about a decade ago, starting with simple lab tests on everyday timber. They took ordinary wood, stripped away the light-blocking lignin through a chemical soak, and filled the leftover structure with a clear resin or polymer. The result? Panels that glow softly with transmitted light, yet hold up far better than brittle glass.

Early work at places like the KTH Royal Institute of Technology in Sweden showed promise right away, with samples proving tougher in drop tests and less prone to cracks. That initial breakthrough sparked worldwide interest, as teams refined the process to improve clarity and reduce costs.

What stands out is how this material keeps wood’s natural grain faintly visible, adding a warm, organic feel absent in cold glass sheets. Unlike fully clear plastics, it diffuses light gently, creating cozy interiors without harsh glare. By 2020, U.S. Department of Agriculture scientists highlighted its edge in real-world use, noting that it bends under force rather than shattering into dangerous shards.

These qualities make it a practical swap for homes and offices chasing sustainability without sacrificing style.

How It’s Made, Step by Step

Creating translucent wood starts with abundant, fast-growing trees like balsa or poplar, keeping costs down and the environment green. The key trick involves boiling thin wood slices in a mild alkali solution to dissolve lignin, the brownish stuff that makes wood opaque. Next comes a bleach rinse to remove any residual material, leaving a spongy cellulose scaffold full of tiny air pockets. Finally, workers impregnate it with epoxy resin or a bio-based polymer under pressure, then cure it to lock in transparency.

This method avoids exotic gear; most steps fit existing factory lines for laminates or plywood. Recent tweaks, such as using egg whites and rice extracts as natural binders, further reduce costs while maintaining durability, as shown in tests by Kennesaw State University researchers. The whole process emits far less carbon than melting silica for glass, and it recycles wood scraps that might otherwise rot in landfills. Panels emerge lightweight, about half the glass’s heft, easing installation in high-rises or retrofits.

Beats Glass Hands Down

Strength sets translucent wood apart in ways glass can’t match. It shrugs off impacts five times better, flexing to absorb energy rather than splintering, a huge safety win for windows in storm-prone areas. Insulation shines too: its cellular structure traps heat like double glazing, slashing energy loss by up to 25 percent in buildings.

Studies in journals like Advanced Functional Materials report that its thermal conductivity is one-fifth that of glass, meaning cozier winters and cooler summers without cranking the thermostat.

Light transmission hovers around 80 to 90 percent, close to glass for bright rooms, though with a soft frosted finish ideal for privacy screens. Fire resistance improves over plain wood, as the polymer filler chars slowly instead of flaming up.

Weight savings let architects design larger spans, cutting steel needs in frames. Overall, it trims lifetime costs; one analysis pegs energy savings alone at justifying the switch within years for commercial spaces.

Green Benefits for a Warmer Planet

Eco-cred runs deep with translucent wood, rooted in renewable forests over mined quartz. Production skips fossil-fuel ovens, generating a fraction of glass’s 25,000 metric tons of yearly CO2 in construction alone.

Being biodegradable, it breaks down harmlessly at the end of its life, unlike plastics that linger in the ocean. Carbon storage adds another layer; the cellulose locks away CO2 from growth, and studies claim it’s 10 million times greener than some polymer boards.

In buildings, it curbs emissions by optimizing heat flow, potentially trimming office cooling demands by a third. Smart versions block 100 percent UV rays while regulating glare, no electricity needed, perfect for Gulf resorts or U.S. sunbelts where your work on infrastructure highlights mega-projects. Pair it with solar coatings, and panels turn into power generators, aligning with trends in smart urban builds you often cover.

Real-World Uses and What’s Next

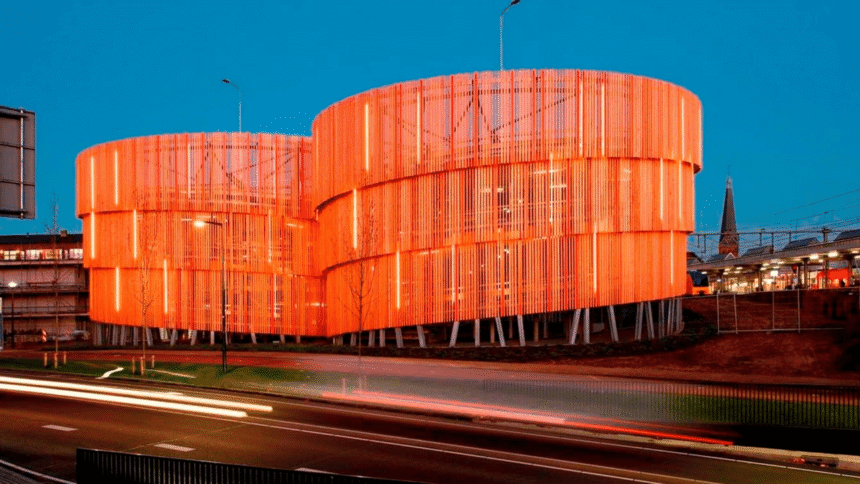

Windows top the list, but translucent wood stretches further. Picture glowing facades on high-rises, diffusing daylight deep inside without LEDs. Early prototypes clad a model birdhouse, keeping it 9 to 11 degrees cooler than glass under lamps. In furniture, it crafts lightweight tables or partitions with a luxe, natural vibe for Middle East luxury spots you track. Add silver nanowires for conductivity, and touchscreens or wearable tech enter the mix, though teams eye graphene for full green status.

Scaling hurdles remain, such as matching crystal-clear views or hitting mass-market prices under $10 per square foot. Labs push bio-resins from plant waste to dodge petroleum entirely. By 2026, pilot projects in Europe will test full-window installs, with the USDA eyeing U.S. codes soon. For construction pros in Bengaluru or Dubai, this means lighter loads, safer sites, and LEED points galore.

Challenges to Overcome

No material’s perfect. Current haze limits sharp views, making bathrooms more suitable than living rooms. Scaling needs larger sheets without defects, and resin costs hover at 3x glass’s upfront cost. Durability shines in labs, but decades-long weathering tests lag. Regulations treat it as “experimental,” slowing approvals despite safety data.

Researchers counter with hybrid glazings, blending float glass with it. Cost drops as patents expire and popular farms expand. Your focus on Gulf infrastructure could highlight trials in arid zones, where insulation helps mitigate extreme swings.

Translucent wood arrives at a tipping point for green building, blending nature’s toughness with modern needs. It promises cuts in energy bills and carbon footprints without skimping on light or looks. As mega-projects rise from Texas to the UAE, this humble tweak to timber could redefine windows, proving old materials hold new secrets.

Image Credit – re-thinkingthefuture.com